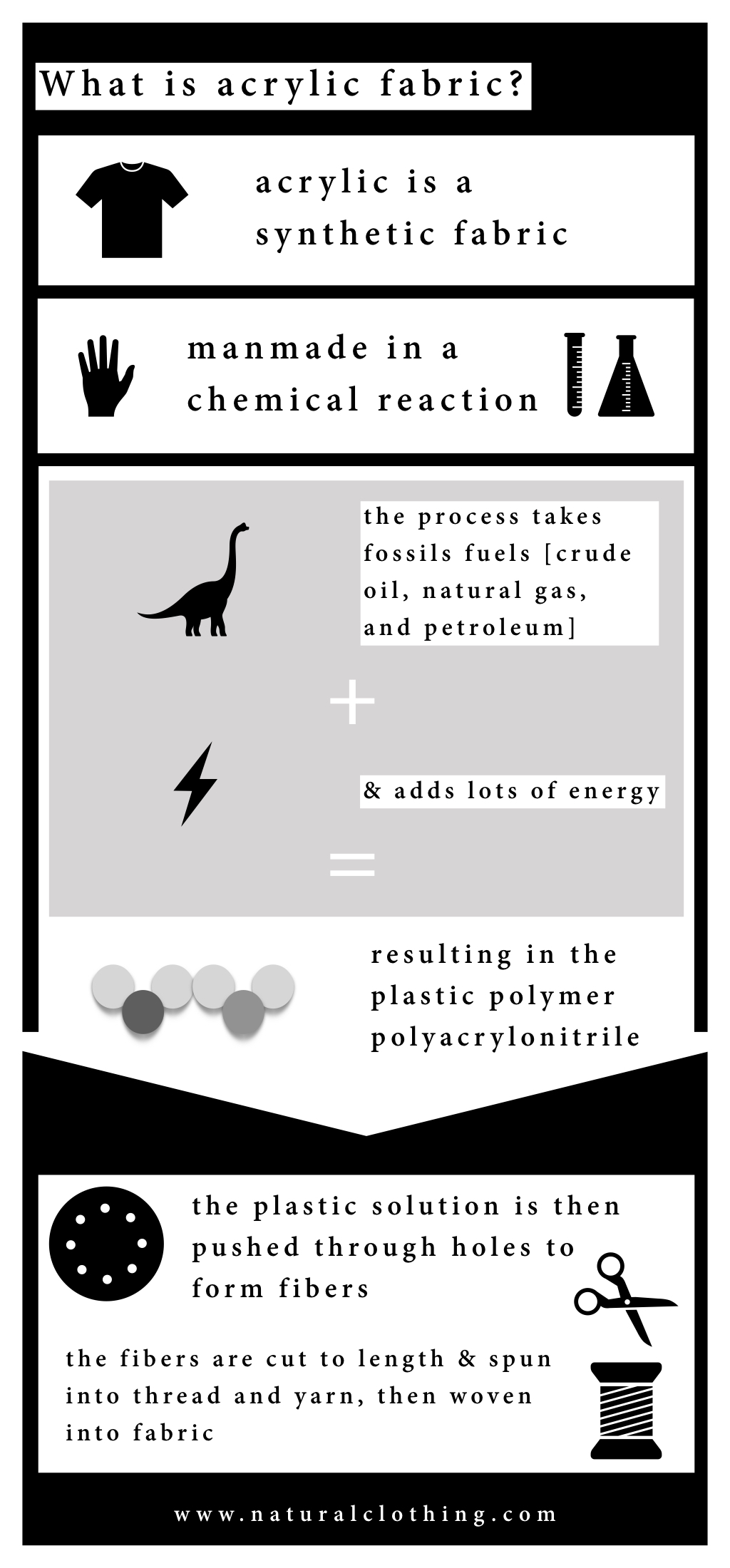

Acrylic fabric is made with plastic threads. The plastic threads are made of a manmade polymer fiber created from fossil fuels through a chemical process. Acrylic fabric is made in a way similar to the production of polyamide fabric (or nylon fabric) and polyester fabric.

how is acrylic fiber made?

When heat and pressure (energy) is applied to the fossil fuels (petroleum, natural gas, and less commonly, coal), polymerization occurs and a plastic solution is formed. Polymerization describes when two or more molecules bind into a repetitive molecular chain. After polymerization, the plastic solution is in a viscous form. This means the solution’s state of matter is somewhere between a solid and a liquid.

The plastic solution is then spun through spinnerets. Spinnerets are tools with holes of certain size and shape that create the desired properties in the thread product, whether it be thicker, thinner, hollow, or solid. The viscous solution spins through the spinnerets and exits into either air or water where it solidifies. The acrylic fibers are then washed, dried, and cut into long or short length fibers.

what is acrylic fabric made of?

Once the acrylic fiber is washed, dried, and cut, it is ready to be spun into thread. The threads are then woven into fabric, with acrylic fabric as the end result. It’s common that acrylic fiber and acrylic threads be woven with other types of fiber to create what’s called a ‘blend’. This is usually done as a cost cutting measure, since synthetic fibers are often cheaper than natural fibers. So if you see a shirt advertised as a ‘cotton-blend’ or ‘wool-blend’, it isn’t just cotton or wool, there’s another fiber in the mix.

what are the properties of acrylic fabric?

Acrylic fiber closely resembles the look and feel of wool fibers. Acrylic fabric is lightweight, warm, and soft to the touch. It is thus used in place of wool or blended with sheep wool or cashmere. Common end products of acrylic fabric include sweaters, hats, socks, and knitting yarn.

Like polyester and nylon, acrylic fabric is hydrophobic – meaning it repels water. This can lead to bacteria growth in the fabric which may compromise the structure and cause odor. It also means that acrylic fabric is more likely to create static electricity and cling. Acrylic fabric is also flammable and can be extremely difficult to extinguish, whereas wool is extremely difficult to light.

Because of these properties, acrylic is not a good material for clothes. It is usually blended with natural wool fibers or used to mimic wool not for its properties, but for manufacturers to save money on cost of materials.

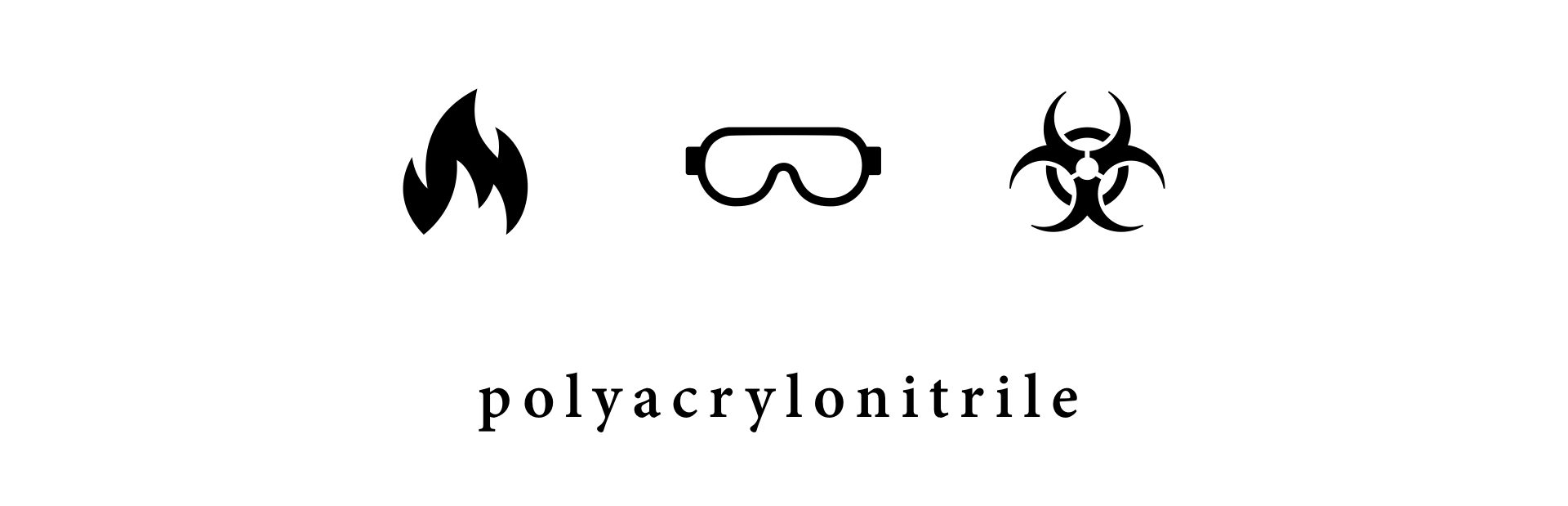

workplace hazards of producing acrylic fabric

Acrylic fiber is made from the polymer polyacrylonitrile. Polyacrolonitrile is a flammable, colorless liquid that is created from polypropylene. The EPA found that inhaling polyacrylonitrile gives the victim similar symptoms to cyanide poisoning. In fact, when exposed to polyacrylonitrile, our bodies metabolize the chemical into cyanide. This metabolization can take place after exposure to the chemical through skin contact, ingestion, or inhalation. Polyacrylonitrile is also cited as a potential cancer hazard.

the short product life & long landfill life of acrylic fabric

On its own, acrylic fabric is not resistant to abrasion. Because of this, acrylic fiber is often blended with more resilient fibers to create a more durable product. Acrylic fabric is also highly likely to pill. Needless to say, the product lifespan of acrylic fabric clothing is not considerably long. Then it enters the landfill, where acrylic fabric can last up to 200 years and release toxic chemicals into the environment on its long journey to decomposition. Two hundred years. If you thought that picture of your grandma in the dress with puff sleeves was funny and outdated, just wait until your great-great-great-great-great grandkid finds your Forever21 DayGlo crop top. Because it might still be around! Very pilled, bacteria ridden, and possibly singed. Not to mention, leaching toxins. So if nothing else, wear biodegradable clothing to save face with your heirs.

how does acrylic knitting yarn compare to natural fiber yarn?

Acrylic fiber based knitting yarns are often available at lower prices than natural fiber yarns. However, they lack some of the desirable properties offered by natural fibers. Unfortunately, acrylic yarns are not as soft as natural fiber yarns and do not have the ability to felt. Acrylic fiber yarns can also cause discomfort to the knitter, because the yarn does not have give. When finishing a garment, acrylic yarn requires heat to let the final product set (or relax). With these properties in consideration, natural fiber yarns made with wool, cotton, linen, or silk, are a worthy investment.

what is modacrylic?

Modacrylic is a modification of acrylic fiber. It is commonly used in wigs, hair extensions, fake fur, and some protective clothing. Modacrylic is modified to have flame retardant properties.

[…] What Is Acrylic Fabric? How Acrylic Fabric Is Made & Its Properties. [online] Available at: https://www.naturalclothing.com/what-is-acrylic-fabric/ [Accessed 4 Oct. […]

Thank you for this great detail on acrylic fabric