Ever wonder what’s in your clothes? Why one shirt is particularly itchy, one is super soft, one you’ve had forever and it’s still perfect, one might be always stinky, or one shrank in the wash? Here we’ll run through the three basic fibers that make up clothing fabrics: natural fiber, semi-synthetic fiber, and synthetic fiber.

For a quick guide to the sustainability of each of these fabrics, you can read our guide here. For more in depth information, feel free to check out the page for each fabric.

natural fiber

A natural fiber is collected from plants or animals. It’s that simple.

Natural fibers include: silk, cotton, cashmere, sheep wool, alpaca, hemp, linen, and jute.

Natural fibers tend to be gentler on skin, easier to wash and care for, and are less prone to bacteria growth. They also tend to be more sustainable for the environment than synthetic fibers.

semi-synthetic fiber

Semi-synthetic fibers are derived from a naturally occurring fiber through a chemical process. So basically, the naturally occurring fiber is harvested, broken down, and then reconstructed. This is most commonly done with cellulose. Cellulose is a structural component abundant in plants. The cellulose is extracted from the plant, made soluble, and then spun into fiber. In many cases, this process can be done sustainably and yields a very versatile fabric.

Examples of fabrics made from cellulose include: rayon, viscose, modal, lyocell, and Cupro.

synthetic fiber

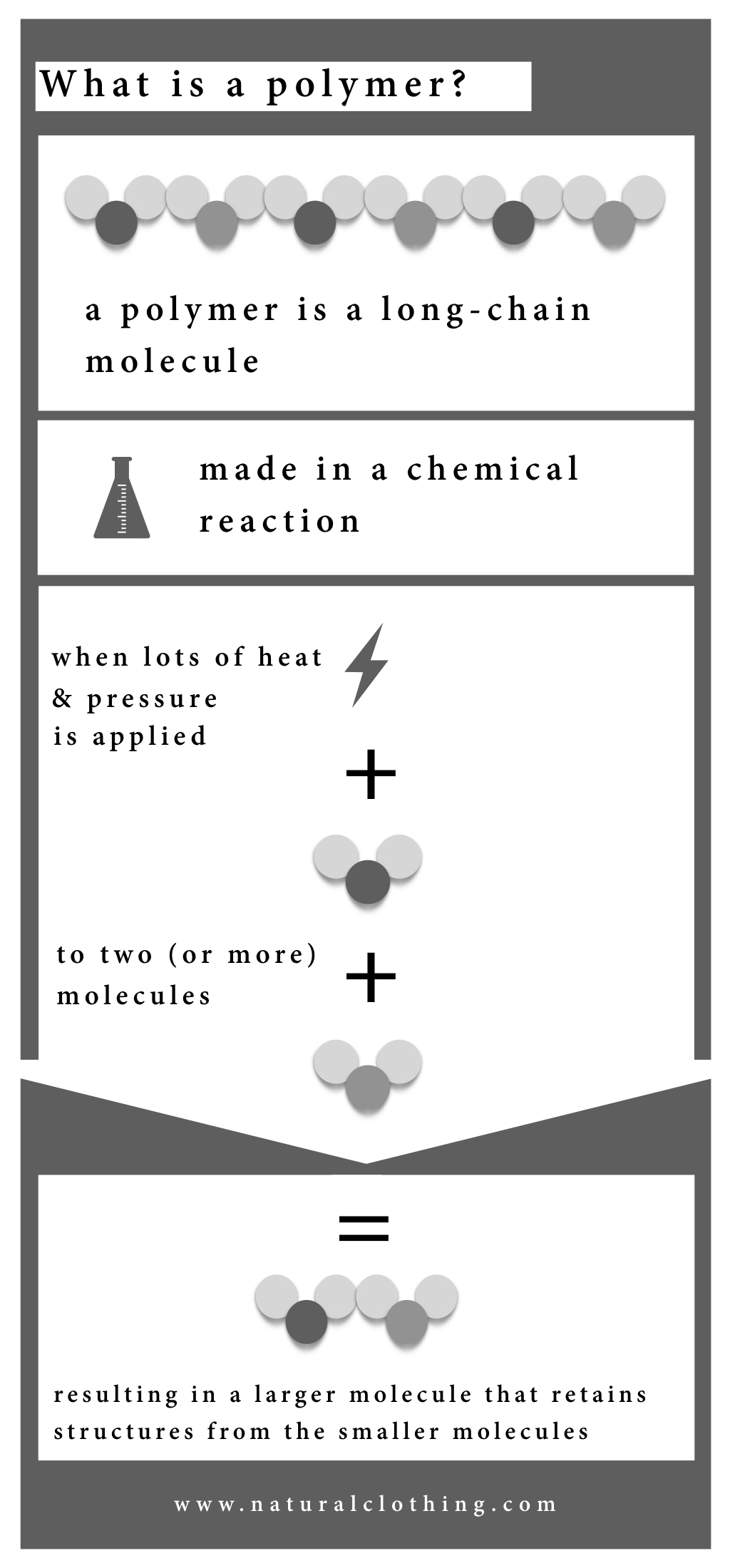

Essentially, most synthetic fiber is plastic. Synthetic fiber is manmade through the process of polymerization. In this case, polymerization requires high amounts of energy to be applied to fossil fuels.

Common synthetic fibers include: polyester, nylon (polyamide), acrylic, spandex, olefin, and those that are wrinkle free, stain resistant, or pest repellent.

Manufacturing of synthetic fibers begins with natural gas, coal, and oil. Chemicals like sodium hydroxide and carbon disulfide are extracted from these fossil fuels. The chemicals are polymerized to create a viscous plastic polymer solution.

The chemical solution is then pushed through spinnerets (a tool with tiny holes) into air or water. As the chemical solution comes out of the spinnerets and cools, it solidifies and forms threads. Then, these threads are spun and woven together into threads, yarns, and textiles. Additional chemical processes are used to treat the textile depending on the desired qualities of the final product (water resistant, stain proof, wrinkle free, antistatic, etc.).

Unfortunately, the production of synthetic fibers has a high impact on the environment. The production of synthetic fibers uses large amounts of energy and non-renewable resources. It also creates a significant amount of byproducts and manufacturing waste. Further, clothing made with synthetic fiber sheds microscopic pieces of plastic throughout their product life. Additionally, when synthetic clothing is thrown away, it will stay in landfills for hundreds of years while leeching toxins.

In terms of personal health, synthetic fibers are not our first choice. Synthetic fabrics are more likely to harbor bacteria and absorb environmental toxins. Studies have also revealed that even plastics tested to be BPA-free emit endocrine disruptors (similar to BPA) when exposed to normal everyday wear.

[…] product is still biodegradable, even if they are semi-synthetic, and does not release toxins like fully synthetic materials do. […]